[ad_1]

MARCY, New York — From afar, the brand new Wolfspeed manufacturing facility in upstate New York appears to be like like every other giant company workplace constructing, with an unassuming grey exterior and huge glass home windows. However hidden inside is a high-tech plant that’s virtually totally operated by a fleet of robots programmed to construct semiconductors with a excessive stage of precision. The scene is a far cry from the handbook labor of the 20th-century Ford meeting line, and it simply is likely to be the way forward for American manufacturing, not less than in line with the politicians and executives who celebrated the plant’s grand opening in late April.

To mark the event, just a few hundred folks, together with Wolfspeed staff, buyers, and native officers, gathered in a big tent only a quick stroll away from the manufacturing facility’s entryway. A collection of audio system, together with Wolfspeed CEO Gregg Lowe, took turns boasting in regards to the plant’s significance — for native jobs, for know-how, for combating local weather change, and even for American prosperity. Additionally in attendance was Eric Bach, the chief engineer of Lucid Motors, an electrical automaker that, only a few hours earlier, introduced it will begin utilizing Wolfspeed’s chips in its vehicles. The star of the present: New York Gov. Kathy Hochul, who claimed the brand new facility was a part of the “best comeback within the historical past of this nation” earlier than she took a spin in one of many luxurious Lucid EVs.

“This has to occur. Now not can the nation, america, be dropped at its knees due to provide chain points,” Hochul informed Recode. “Make them right here! Make them in New York! We’ll put the cash behind it.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426582/GreggHochulFabWindow_a.jpg)

Wolfspeed’s manufacturing facility is opening its doorways after greater than two years of a worldwide semiconductor scarcity that left cars without parts and the well being care system low on medical devices. To supply extra chips, the Biden administration, with the assistance of state governments, now plans to speculate $52 billion within the chip trade to construct extra factories similar to the brand new plant exterior Utica, New York. The hope is that these crops received’t simply make extra semiconductors; they’ll spur a tech manufacturing renaissance in the identical nation that invented the pc chip and produced Silicon Valley a long time in the past.

This new crop of chip factories, typically referred to as fabs, received’t be prepared in time to resolve the current chip scarcity. These amenities will take years to construct, and even after they’re accomplished, they received’t produce as many chips because the US makes use of. Nonetheless, the federal government thinks the fabs may play a vital function in blunting the impression of a future disaster, like local weather change or one other pandemic. Additionally they would possibly assist the US regain management within the trade it created and catch as much as Taiwan, which makes almost all of the world’s most advanced chips today.

What’s unclear, nonetheless, is whether or not funding the development of latest fabs can be sufficient to make that occur. Constructing a single fab is a big industrial challenge, so constructing a number of — shortly — can be a colossal endeavor. To an extent, the US is attempting to cultivate know-how that, for many years, has been produced by an international supply chain made up of hundreds of corporations, which suggests the success of those new fabs should still rely on different elements of the world. And even because the White Home races to say a much bigger share of the world’s complete chip manufacturing, different international locations, together with Taiwan, are attempting to do the identical factor, which suggests there’s no assure the US will find yourself with the higher hand that it needs.

How America misplaced its selfmade chips

The US as soon as dominated chip manufacturing. In 1947, scientists at Bell Labs created the world’s first transistor, a primary digital change, that may flip a sign on and off. This part grew to become the muse for the built-in circuit, also called a pc chip, which packed a number of transistors right into a single system. Because the know-how developed, new corporations started competing not solely to design chips with extra transistors, but additionally to provide these chips at scale. Excessive-tech manufacturing corridors emerged in Texas and what grew to become Silicon Valley, paving the way in which for superior client gadgets and home equipment, usually constructed with chips made in America.

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426601/GettyImages_528775306.jpg)

The federal government performed a pivotal function in ensuring the US led the cost on this know-how. The Protection Division was often the first customer for early semiconductor startups, and authorities officers typically required corporations to share their designs in order that different companies may use them, too. This help funded initial research that these chip corporations in any other case couldn’t afford and laid the muse for the tech trade we now have right now. The US used this funding technique — typically referred to as industrial coverage — once more within the late 1980s when it spent $900 million on a partnership referred to as Sematech, through which American chip corporations tried to make sure that they wouldn’t be overtaken by rising rivals in Japan. For a time, the program succeeded.

However in current a long time, the US authorities has invested less and less in its homegrown chip trade, whereas different governments together with Japan, Taiwan, South Korea, and, extra lately, the European Union and China, have invested extra. These large subsidies — together with decrease labor prices — have made it less expensive for American corporations to fabricate semiconductors overseas. Some even have taken a “fabless” strategy, and centered their complete enterprise on researching and designing chips reasonably than making them. In consequence, simply 12 percent of the world’s chip manufacturing takes place within the US right now, in comparison with 37 p.c in 1990.

This shift has benefited one firm specifically: Taiwan Semiconductor Manufacturing Firm, or TSMC, a Taiwanese chipmaker that manufactures chips on behalf of different companies. There’s a race to make smaller transistors — so extra of them can match onto a single chip — and TSMC is at the moment successful. Due to all of its manufacturing expertise, Taiwan now makes 92 percent of chips, together with essentially the most superior semiconductors available on the market right now, which have transistors which might be lower than 10 nanometers huge. None of those superior chips are at the moment made within the US, which makes officers very frightened.

“It’s a extremely concentrated provide chain in sure elements of the world like Korea and Taiwan, and that has made our economic system actually susceptible to disruptions as a result of small occasions in international locations can result in giant value will increase for American shoppers and huge shocks to US GDP,” Sameera Fazili, the deputy director of the Biden administration’s Nationwide Financial Council, informed Recode. “They’ve essentially the most superior modern chips, whereas we eat over 30 p.c of these chips.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426636/GettyImages_536193612.jpg)

This concern is predicated, partly, on fears that China may invade Taiwan in some unspecified time in the future and try to take management of its chip-manufacturing capability. However there are different causes to be frightened in regards to the state of US semiconductors. The US doesn’t at the moment make very lots of the most elementary, or legacy, chips, that are sometimes produced where they are often made for much less. These are the chips that grew to become unavailable throughout the pandemic, and that made plenty of know-how onerous to search out and drove up automobile costs. The US will even must manufacture extra chips to maintain its hold on the auto industry, since EVs will doubtless want not less than twice as many chips as their gas-powered counterparts do.

The way to construct a chip manufacturing facility

To make its chips, Wolfspeed makes use of silicon carbide, a semiconducting materials that’s particularly helpful for chips that energy motors, like these in EVs. This silicon carbide comes within the type of translucent discs referred to as wafers, that are delivered from another Wolfspeed plant in North Carolina. That facility has a particular furnace that will get half as hot as the surface of the sun, which is required to refine the fabric. As soon as these silicon carbide wafers are delivered to Wolfspeed’s facility in Marcy, they’re despatched to a producing ground, the place a small military of robots slowly transforms them into sheets of chips.

Chipmaking is extraordinarily delicate — the tiniest speck of mud or human hair can taint a whole batch — so Wolfspeed refines its wafers in a cleanroom, a extremely monitored manufacturing ground with highly effective air filtration methods. Inside this cleanroom, robots shuttle wafers between manufacturing steps whereas technicians monitor their exercise from a close-by management room. This course of consists of lithography, when tiny patterns are printed into the wafer, and one thing referred to as deposition, which includes including layers of metals onto the silicon carbide. As soon as these steps are accomplished, the wafers are despatched to a different facility the place they’re diced into particular person chips. Your entire operation is automated, and on the uncommon event that employees do must enter the cleanroom, they need to put on astronaut-like protecting gear, together with a full bodysuit, a face protect, and boots.

Making chips is an intricate course of, however constructing a manufacturing facility that may do any such manufacturing is much more sophisticated. For one factor, fabs can’t go simply wherever. They must be near a dependable supply of electrical energy, since they’ll use as a lot vitality as 50,000 homes in a single year (they launch a lot of carbon emissions, too). These factories additionally must be close to a big physique of water, which they use to wash and funky down their gear, which, in flip, produces wastewater that needs to be treated. And it’s higher in the event that they’re not notably near any airports or geological fault lines; seismic activity can disrupt the extremely exact equipment they use.

Then there’s the matter of the provision chain. Past the fab, making a chip can contain 70 different border crossings and more than 1,000 steps, and a single disruption in a single nation or throughout a specific step can throw the complete course of off beam. That’s as a result of there are often only a few, if any, different choices for provides when one thing goes mistaken. For instance, only one firm within the Netherlands, ASML, makes the specialised, $200 million lithography instruments that many superior chip fabs depend on. And simply two companies, each based mostly in Ukraine, provide about half of the specialized neon gas that fabs all through the world use to regulate these lasers. In fact, securing all this gear has gotten much more troublesome throughout the pandemic.

“We couldn’t get this. We couldn’t get that,” John Palmour, Wolfspeed’s chief know-how officer, informed Recode. “It was only a fixed provide chain scramble.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426657/Wafer_a.jpg)

All of this implies the price of constructing a fab can vary from $1 billion to $20 billion, relying on the complexity of the chips which might be being manufactured. That is the first motive that the current surge in demand for chips — fueled partly by the demand for extra laptops and extra vehicles — didn’t instantly lead to extra chip fabs. As a result of these crops take years to greenlight and assemble, chip corporations aren’t desperate to spend billions on constructing extra factories, since demand may at all times subside. That is partially why governments usually intervene and supply incentives to construct extra chip factories.

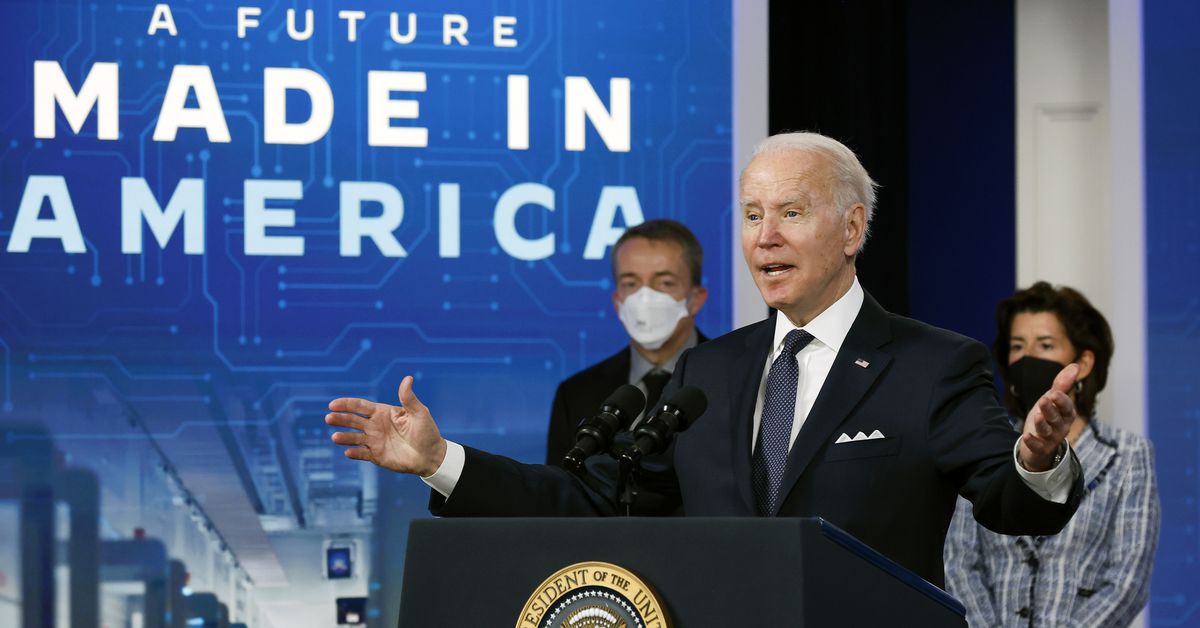

Living proof: New York officers spent decades attempting to draw a semiconductor firm to Marcy, the place New York state has funded a nanocenter related to the SUNY Polytechnic Institute. Wolfspeed solely agreed to take over the location after one other firm backed out and New York supplied to subsidize the fab with a $500 million grant — about half of its complete development prices. Now, much more cash is on the horizon, not only for one other Wolfspeed manufacturing facility, however for probably even larger fabs, together with a new $100 billion megafab in Ohio constructed by Intel, which the administration is hoping will regain “the forefront” and begin constructing the identical form of superior chips that TSMC makes. President Joe Biden, in his most up-to-date State of the Union deal with, mentioned that this facility, as soon as it’s constructed, may present as many as “10,000 new good-paying jobs.”

The massive chip guess

Earlier than any of that may occur, officers say the US must go a $52 billion bundle referred to as the Chips Act, which might subsidize the development of a number of new fabs. At the moment, the invoice is packaged inside a broader proposal referred to as america Innovation and Competitors Act, laws centered on competitiveness with China. Whereas the Home and the Senate model of this plan aren’t precisely the identical, the initiative has the help of Republicans, Democrats, the White Home, and the most important chip corporations. The help from the trade isn’t shocking; every of those corporations may theoretically obtain up to $3 billion to construct a brand new manufacturing facility, and one other $2 billion may be earmarked particularly to construct a fab that may completely deal with extra primary chips utilized in vehicles.

Proponents of the large invoice argue that it’s the naked minimal as a result of different international locations are nonetheless subsidizing chip manufacturing, too. Again in 2014, China launched a $150 billion effort to spice up its personal semiconductor trade over the following decade, and the nation has imported fewer and fewer chips in recent times. South Korea plans to spend as a lot as $65 billion on its own national chip initiative. The European Union additionally has its own $49 billion Chips Act, and its member international locations, together with Spain and Germany, will quickly launch their very own incentive packages.

“The clock is ticking,” John Neuffer, the CEO of the Semiconductor Trade Affiliation, a commerce group that represents American chip corporations, informed Recode. “Choices are being made right now as to the place to web site these fabs.”

:no_upscale()/cdn.vox-cdn.com/uploads/chorus_asset/file/23426699/LucidRibbonCutting_o_a.jpg)

Not everybody loves this strategy; it’s successfully a corporate subsidy for corporations which might be already extraordinarily worthwhile. Sen. Bernie Sanders has been extremely vital of the Chips Act, and has mentioned that chip corporations ought to have to surrender equity in exchange for large grants. Others have argued that these corporations would construct new factories within the US no matter federal incentives, since in addition they have causes to avoid potential geopolitical conflict. And critics level out that chipmaking shouldn’t be fairly the jobs-creator that it’s typically marketed as, with most precise chip manufacturing being done via automation.

There’s no assure the funding will work. The US might not have sufficient of the specialised employees that chip manufacturing requires to help the variety of fabs that officers need. Will Hunt, an analyst at Georgetown’s Middle for Safety and Rising Expertise (CSET), estimates that eight new fabs might require not less than just a few thousand foreign workers, since many of those amenities want to rent folks with earlier expertise working in semiconductor manufacturing. One other concern is that the US’s lengthy regulatory and permitting process may decelerate the development of latest factories, and the US already builds new fabs at a slower charge than international locations in East Asia. Even after these amenities are constructed, they could not produce the variety of chips or jobs that companies promise.

A senior financial official on the White Home informed Recode that whereas the $52 billion will enhance American chip manufacturing, it received’t be sufficient to provide the variety of chips the US consumes. Nonetheless, the federal government thinks that gaining this manufacturing experience might be vital throughout a future emergency. In spite of everything, the pandemic has illustrated time and time once more that when provides are quick, international locations will attempt to safe the world’s most sought-after merchandise — whether or not it’s chips, masks, or vaccines — and might even use them as a approach to affect worldwide relations. Governments would reasonably different governments be depending on them than the opposite means round. In different phrases, they need bargaining chips.

So it’s not shocking that semiconductors have turn out to be that leverage. These tiny little chips are ubiquitous and have turn out to be a necessity in most individuals’s on a regular basis lives. There’s no indication that’s altering anytime quickly, particularly since extra highly effective gadgets — which use much more highly effective semiconductors — are at all times being rolled out. So long as the world is determined by this know-how, international locations will need as a lot management over chips as they’ll get. That signifies that even with Wolfspeed’s manufacturing facility now open for enterprise, the US nonetheless has an extended street forward.

Source link